We are getting back into the boat projects again. One project that has been sitting on the shelf here in Florida is the mainsheet traveler. The traveler allows us to trim the main sail by controlling the position of the main boom. Our traveler is almost 35 years old and in pretty bad shape. I won’t go into to much detail but the paint was peeling, terrible corrosion, and all the sheaves (pulleys) were cracked or disintegrated. It was barely functional when we removed it. Well today, the task of rebuilding the traveler is complete. We disassembled and cleaned the parts, stripped the paint, primed and repainted, replaced the sheaves, and replaced all the hardware.

Start:

Disassembly actually consumed the most amount of time:

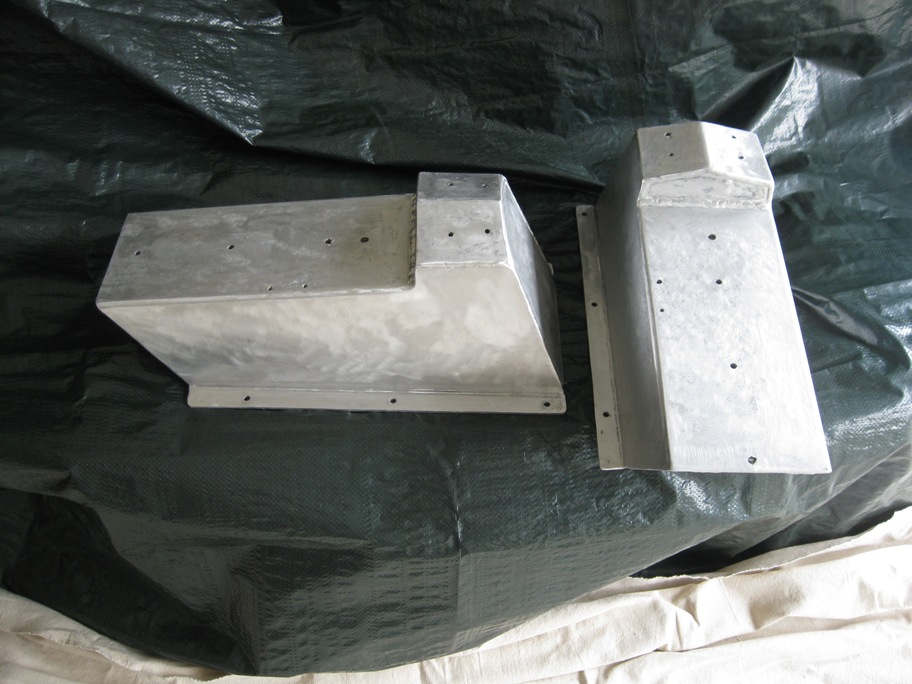

Stripped down to bare aluminum:

Awlgrip primer and Matterhorn white paint:

I had to rebuild the blocks (pulleys):

All cleaned up with new sheaves and hardware:

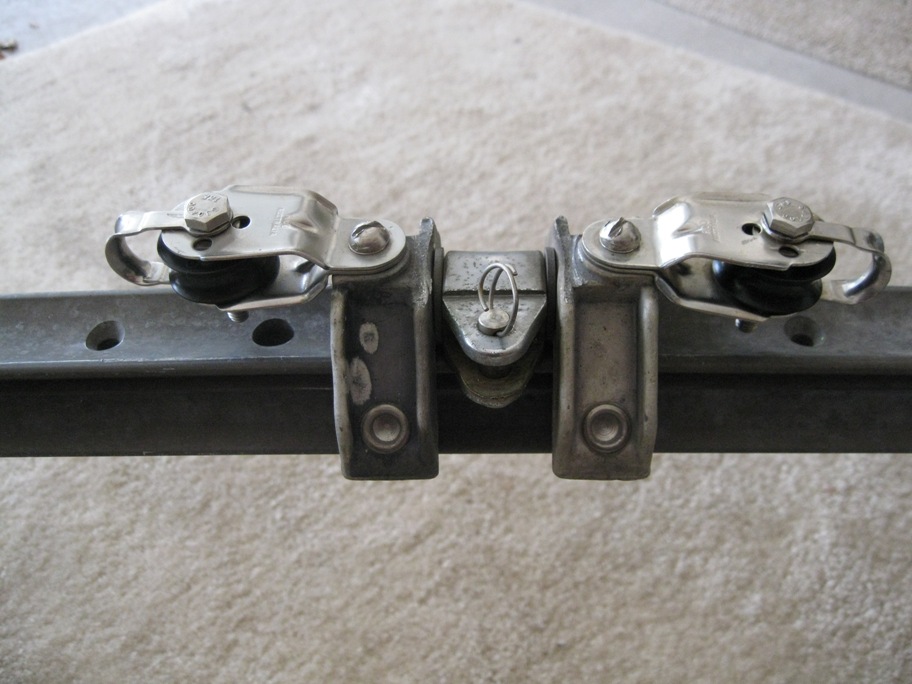

The blocks are now through bolted and secured with lock nuts. They spin feely and should make the entire thing much easier to use:

I wanted to replace these bocks on the traveler car but could not get them to come off:

Since I couldn’t get the whole block to come off I ended up drilling out the center and replacing the sheaves and hardware. Replaced the old plastic with roller bearing delrin sheaves::

It will be much easier to replace these sheaves in the future:

Works perfectly:

All put together. The track is now fastened with counter sunk machine screws and lock nuts.

In addition to the traveler we are replacing all the associated blocks etc. that route the mainsheet from the cockpit, through the traveler, and to the main boom. The blocks were original 1978 and made of aluminum and plastic. We found a company in California, Garhauer Marine, which manufactures their own products and has great customer reviews. These blocks etc. are made of stainless steel with delrin sheaves that spin on roller bearings, they are really sweet! They cost about 70 percent less than the original equipment and they’re made in the US, what a surprise that was!

That’s it for that project. We are plugging along with the watermaker. I have ordered a bunch of fittings and parts that should enable us to complete the three main modules, motor and pump, pressure vessels (filters), and the control panel. Once these modules are complete we will be at a standstill until we return to Maine. Once they are installed we will be able to wire and plumb everything.

We can’t wait to get back, finish what we can and get back in the water! Looking forward to seeing everyone again!

Too bad you couldn’t get the others off. The new ones look really nice. Will try to get back on board and look at open areas for the water maker when the weather clears a bit. Sprin in Maine you know. Talk to you soon.

Bob

At least the sheaves are new…

I was looking online to repaint a traveler track and your info came up. I, also have a Pearson 424, #131, and heres a question or two:

-what did you use to repaint the actual track?

-port riser has accessible bolts, how in the world did you get the starboard riser off (cut into head ceiling?)

You should consider cutting a half circle on the outboard face of each riser. This allows debris and dirt to slide through and also allows you to access the bolts for the track and blocks!

A lot of my through bolts were leaking which required epoxy repair!

I left my starboard riser in place and painted it there.

Thanks for the comment, I emailed you with answers!