We are still hard at it and making some progress. The weather has not been cooperating and we have run into a couple of snags but over all things are going well. Nothing overly exciting to report but here are a few pictures.

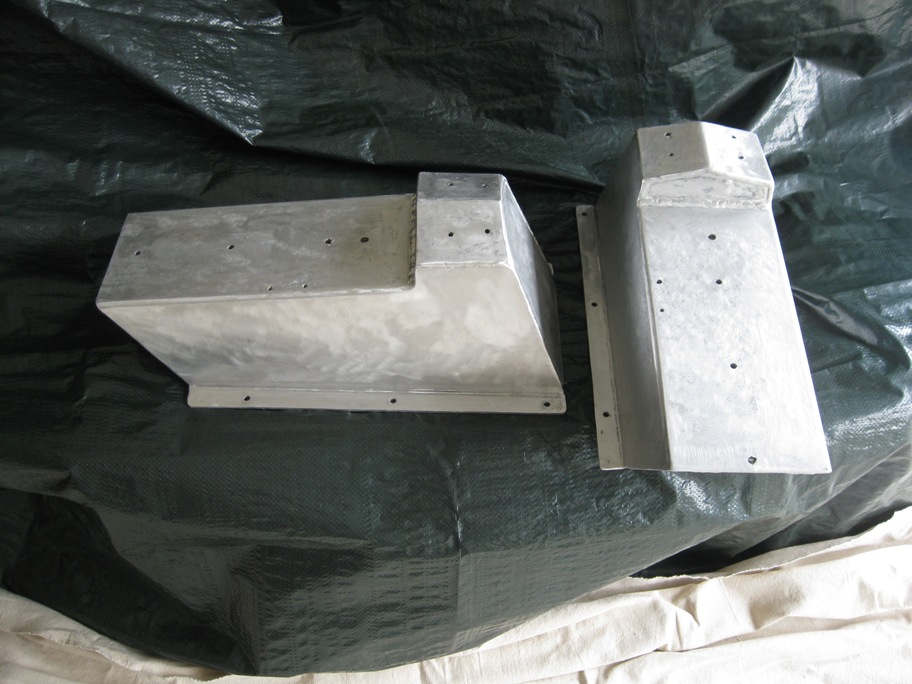

We were able to remove the covers/hatches for the anchor locker, cockpit lockers, and aft companionway. We cleaned, sanded and primed them with Awlgrip 545 primer. On the next sunny day we will paint them. We are actually painting the entire boat, top to bottom, this is just one part of the process.

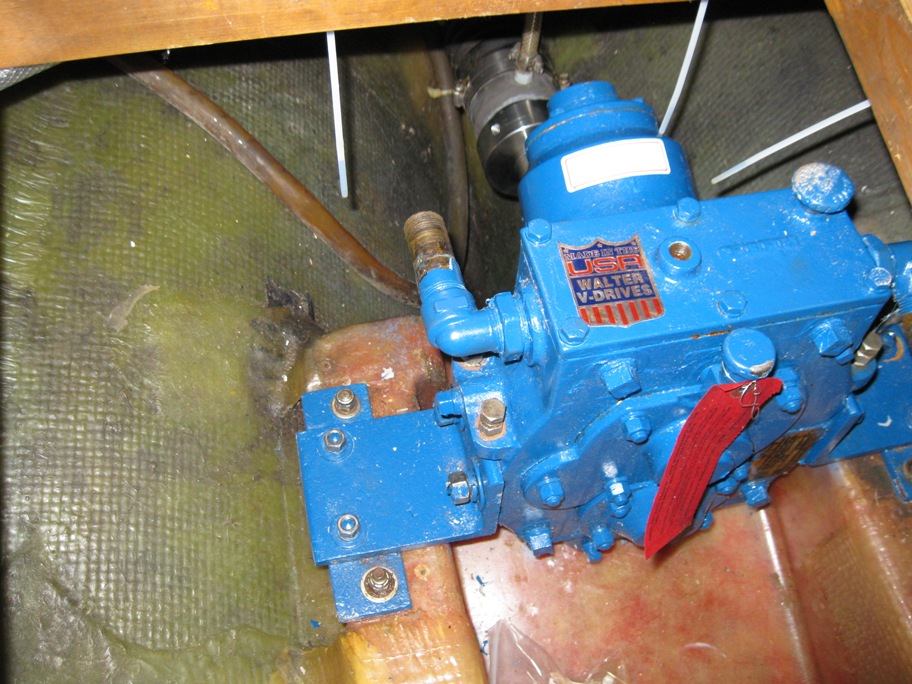

We did run into a little snag with the engine. While positioning the engine into its final resting place we ran into some clearance issues and had to pull it back out to investigate. Fortunately the problem was easy to rectify and relatively inexpensive. We are waiting on one part and once we receive it, we will reinstall the engine.

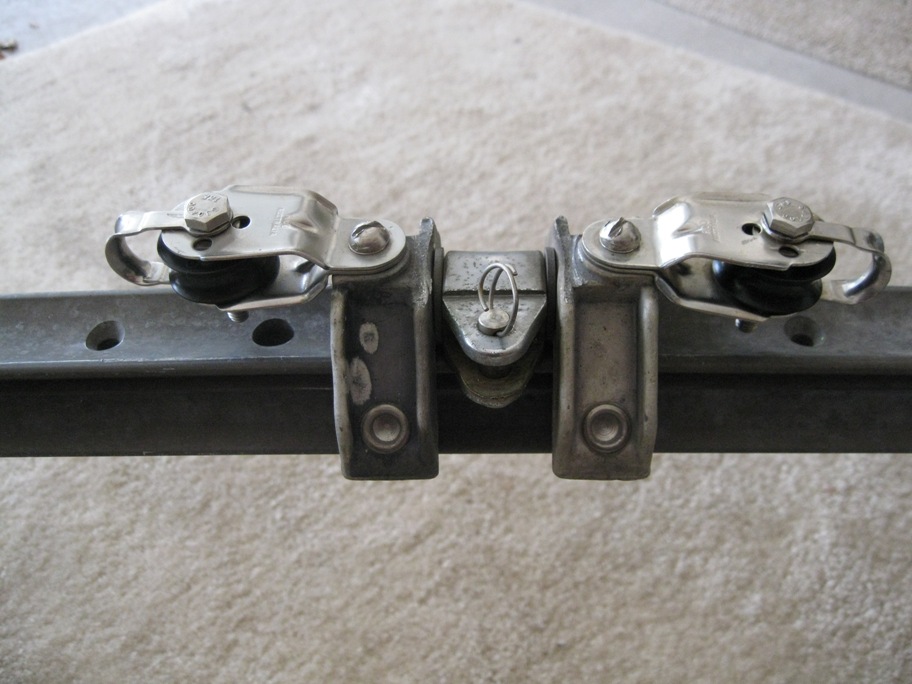

Another part of the engine installation is the drive shaft. This shaft is in two parts which makes it easier to position the engine and align everything properly. Well our drive shaft was rusted together and I bet had not been apart since it was first made (35 years ago). After three days, a whole lot of PB Blaster (solvent), and a little patience, it came free today!! I was able to get the two pieces apart which will make the engine installation go a whole lot smoother! It’s the little things in life…

Since our boat is old and we plan to have it in the water for years, we are going to apply a waterproof barrier coat. The barrier coat prevents water intrusion into the hull which can turn into osmotic blisters. Blisters can be extremely expensive to deal with.

The bottom has to be clean, dry and free of bottom paint. We have begun grinding the bottom down to the gelcoat, fun job and what a mess. Once the bottom is clean we’ll apply the barrier coat and new bottom paint.

That’s all for now…