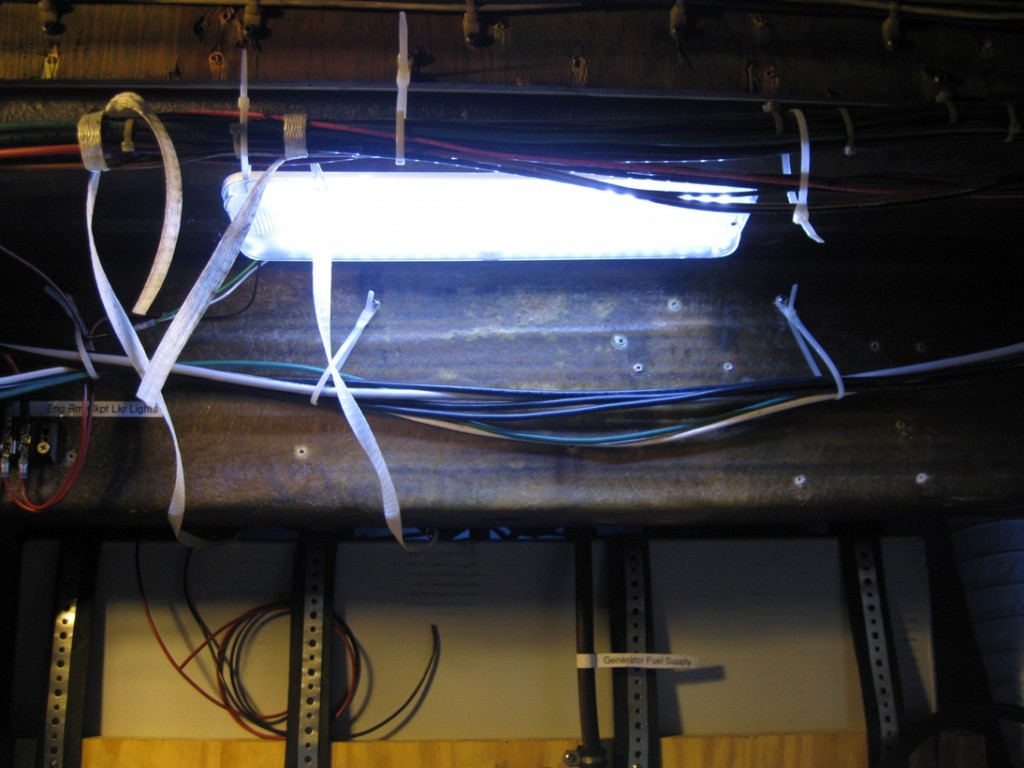

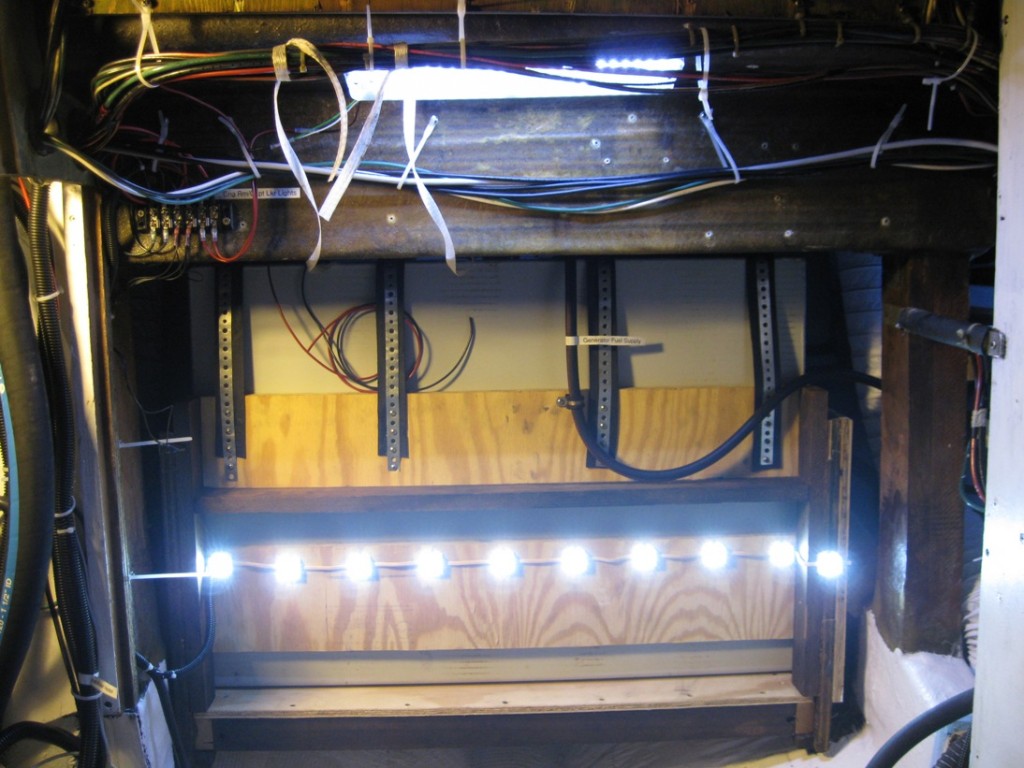

We’re still working toward the goal! We’ve been hard at it. My Mother is varnishing the interior teak pieces. My Sister has been steadily working on the fiberglass, filling holes and cutting others and installing thru hulls. Bob continues to work on the electrical system, a huge job. He has also started the installation of the windlass. We received the new stainless steel hardware for the chain plates and also the new battery cables. We painted the cabin sides, installed the fresh water filtration, rebuilt the foot pumps, started paneling in the head, installed the new pedestal guard and navpods, installed the electronics and wired their data sharing network, and fired up the refrigeration…among other things…

Chain plate hardware from www.stainlesstown.com

Custom battery cables. Bob already installed them.

We wanted to get the cabin sides painted before we install the new ports. We removed the teak eyebrow piece, filled the holes, sanded, and taped. Ready for primer:

Primed then sanded and ready for white Awlgrip:

Awlgrip:

Fresh water filtration:

Tanya hard at work cutting and installing the paneling in the head:

Reinstalled the pedestal (thanks Joan!). Installed the new guard and navpods:

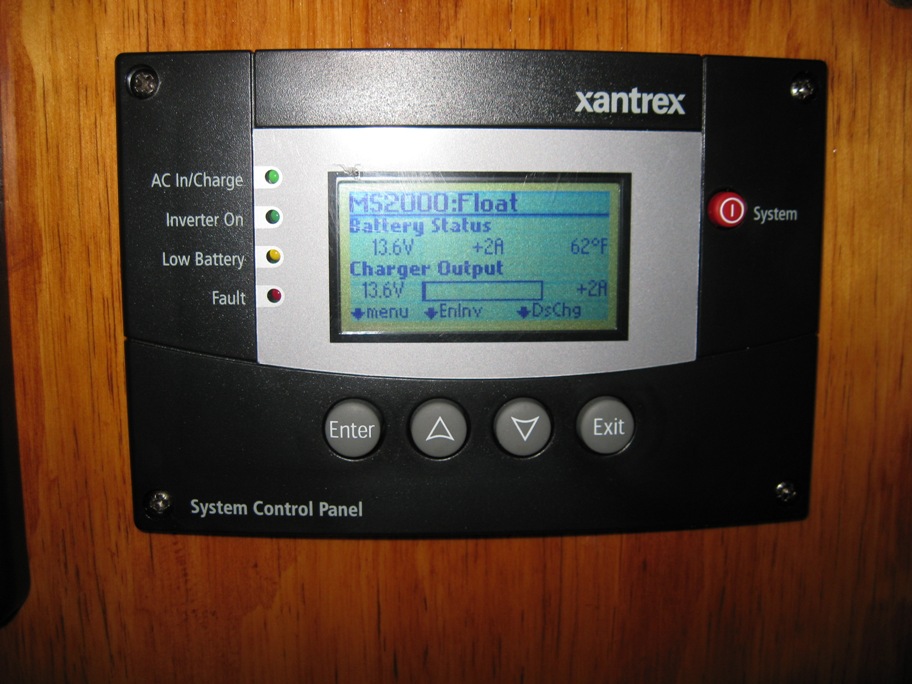

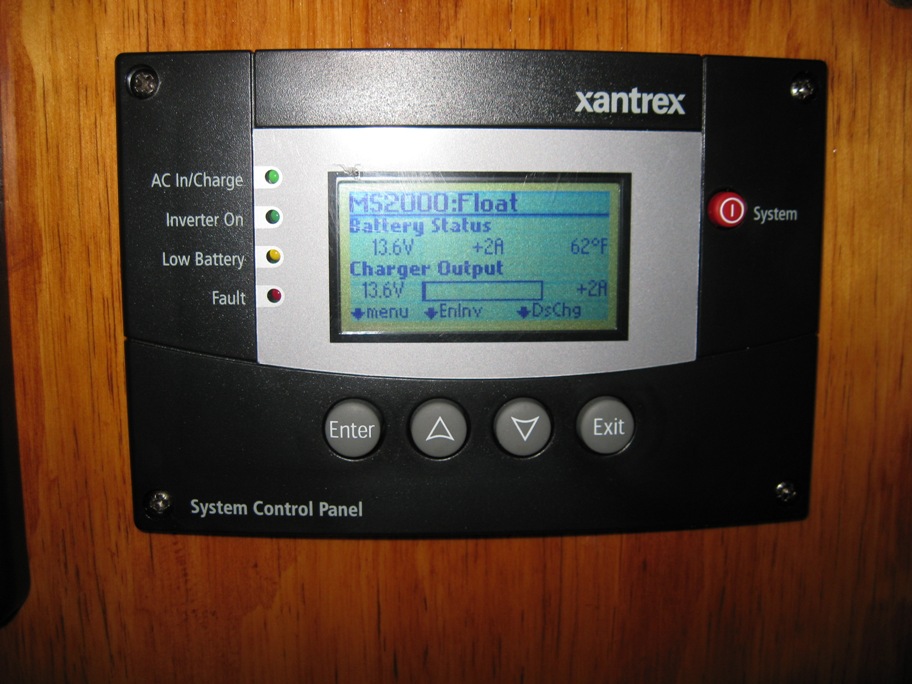

We have installed the electronics. Xantrex inverter/charger remote:

Tanya wiring the autopilot computer:

Computer mounted to the wall. We’ll clean up the wiring when were done with all the wiring.

Electronics at the helm, Simrad NSE8 chart plotter, Simrad autopilot, Furuno depth and wind:

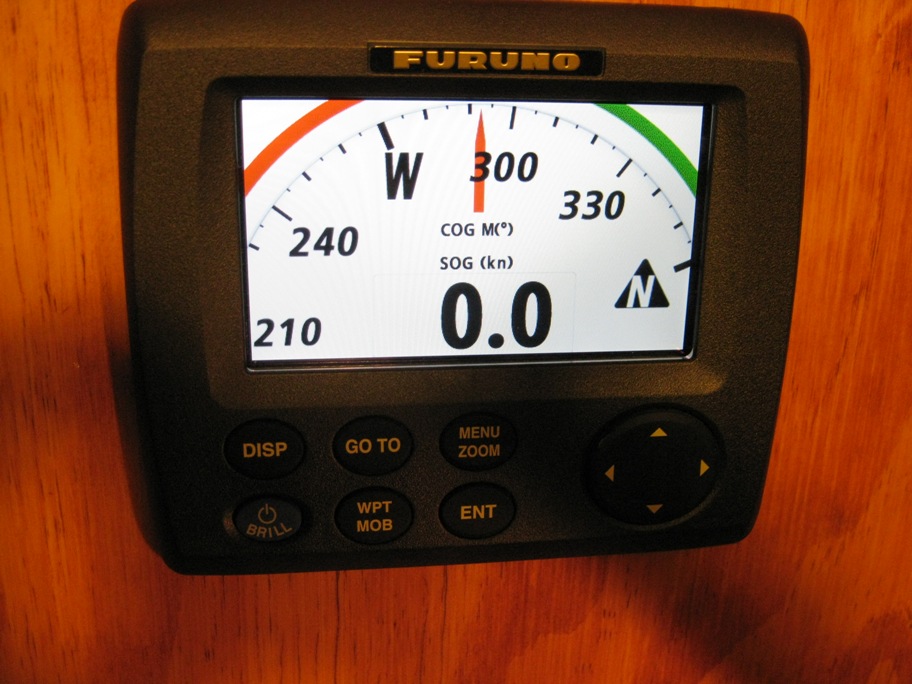

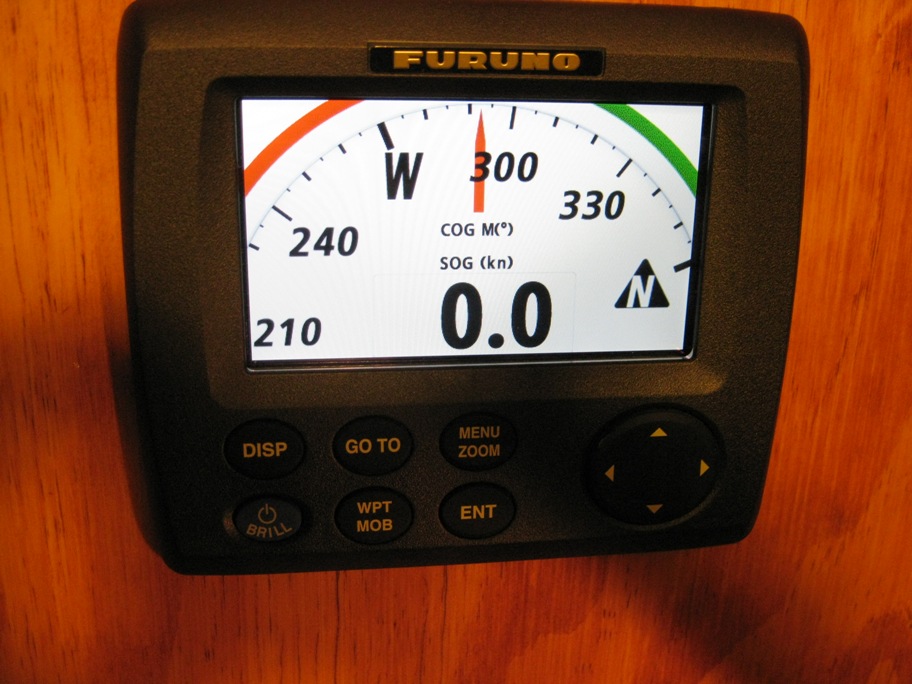

Furuno GP 33 gps navigator at the nav station:

Maretron DSM 250 color monitor at the nav station:

Simrad NSE8 chart plotter:

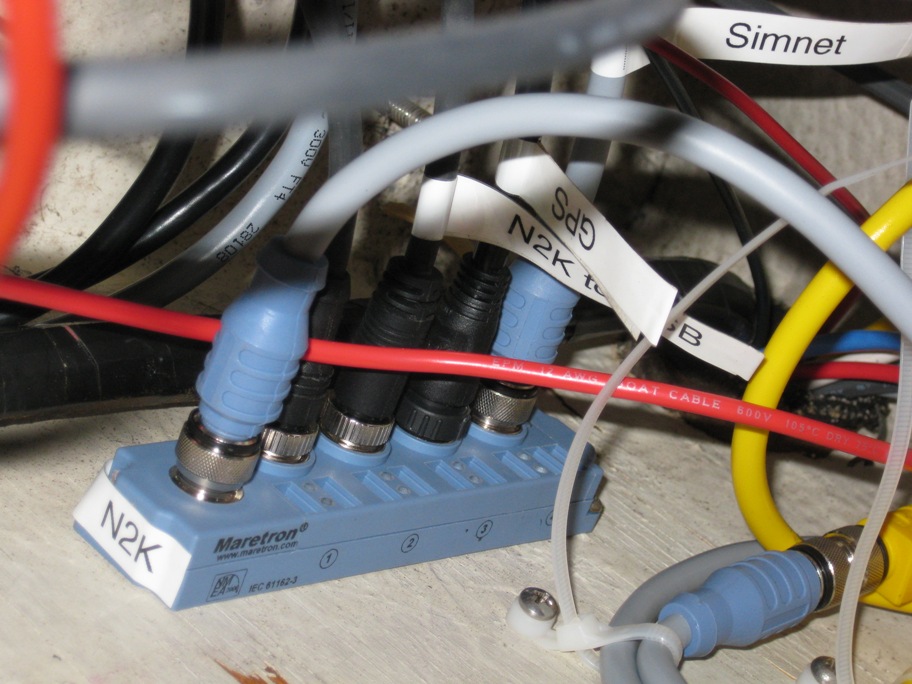

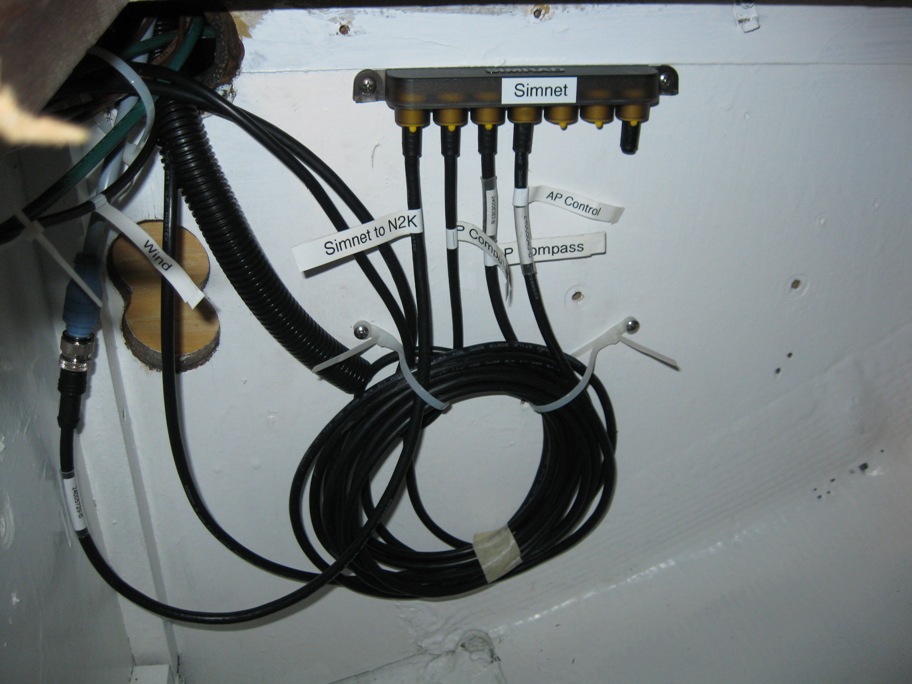

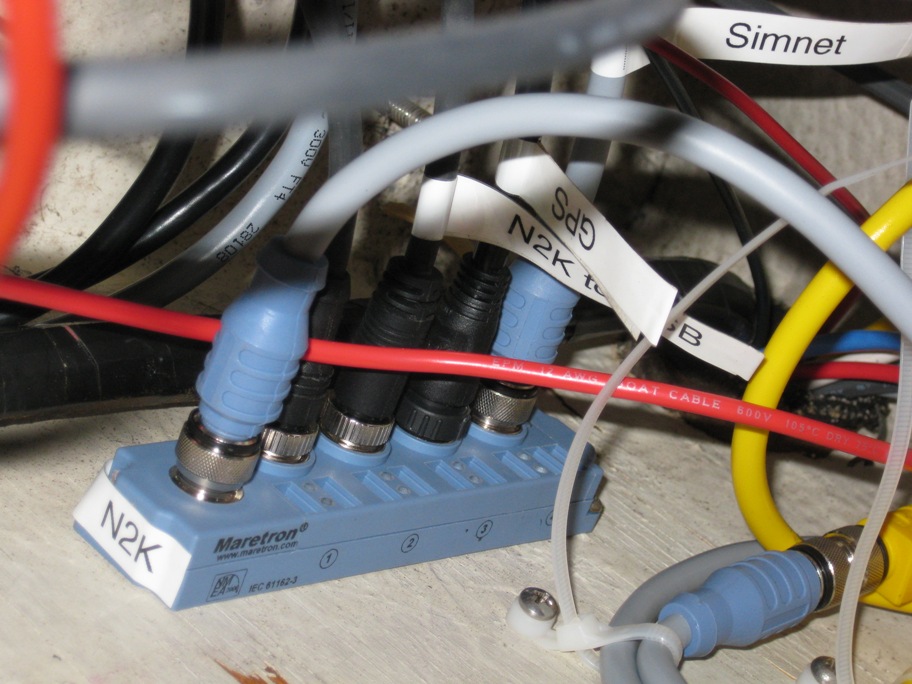

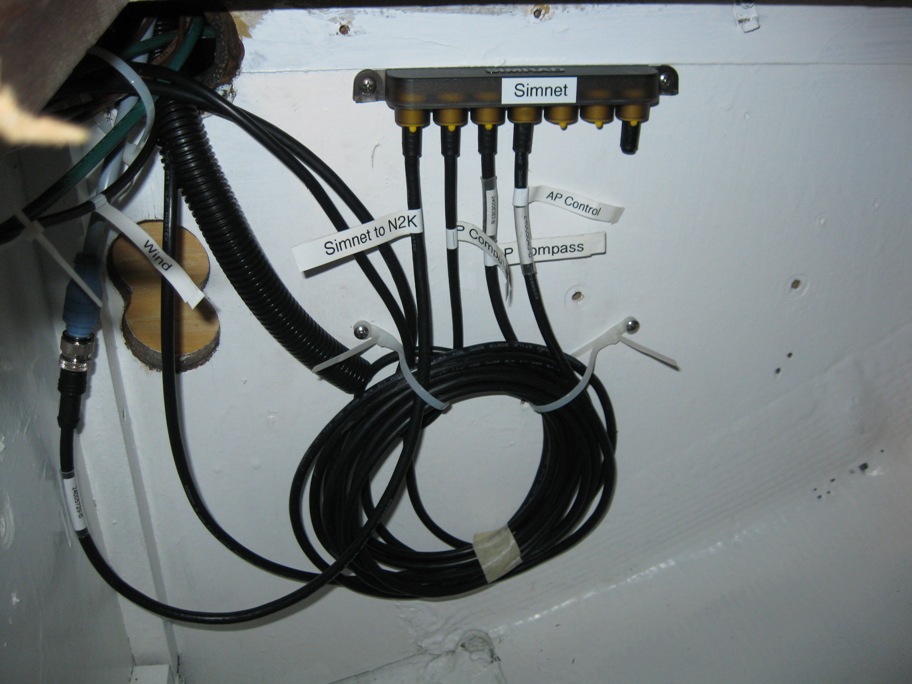

We installed a NMEA 2000 network so the electronics can share data. All the electronics at the nav station and the helm can share data. Yeah, we’ll fix up the wiring later:

The Simrad products use a similar network with different connectors, but use the same data sharing protocol. Their network is called SimNet. We networked the Simrad products together then tied the two networks together. Unbelievably, it all worked! It was actually pretty simple, plug and play for the most part.

We finally tested the refrigeration, it worked perfectly! It took just under an hour to drop the temperature down to 12 degrees F.

Thanks to everyone for all the help!! We’re taking a few days off to go sailing!